Search

Categories List

Message

If you have any questions, please feel free to contact us.

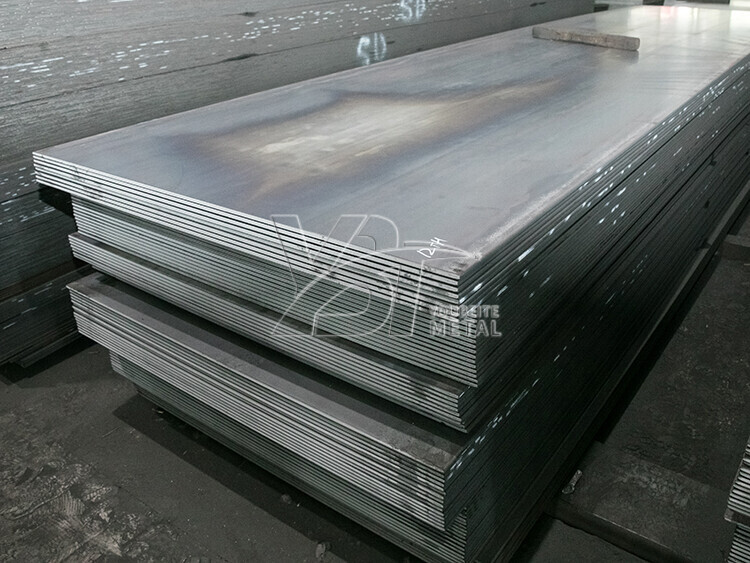

Monel 400 Plate Description

Monel 400 is a corrosion-resistant alloy with the largest dosage, the most wide range of uses, and excellent comprehensive properties. This alloy has excellent corrosion resistance in hydrofluoric acid and fluorine gas media, and also has excellent corrosion resistance against hot concentrated alkali liquid. It is also resistant to corrosion from neutral solutions, water, seawater, atmosphere, organic compounds, etc. An important feature of this alloy is that it generally does not produce stress corrosion cracking and has good cutting performance. Monel 400 plate is widely used in many corrosive applications, particularly in the marine and chemical industries. Monel 400 can be easily machined through conventional machining operations. It is a relatively soft material suitable for thermoforming into almost any shape.

Product Parameters

Monel 400 Chemical Composition

Mechanical Properties

Physical Performance

Scope of Application

Used in marine engineering, chemical and hydrocarbon processing equipment, gasoline tanks and fresh water tanks, crude oil distillers, degassing heaters, boiler feed water heaters and other heat exchangers, valves, pumps, shafts, accessories and fasteners, Industrial heat exchangers, chlorinated solvents, crude oil distillation columns, etc.

Q: How do you control quality?

A : Mill Test Certification is supplied with shipment, Third Party Inspection isavailable.and we also get ISO,SGS,Alibaba Verified.

Q : What are the advantages of your company?

A : We have many professionals,technical personnel, more competitiveprices and best after-dales service than other steel companies.

Q : What extra services do you offer?

A : We can provide you with roll splitting, size cutting, surface treatment(galvanizing, coating and sandblasting) and other services according toyour requirements.

Q: How can l get a quotation?

A : Kindly provide us your details request (item No, style, logo, size, material, surface treatment, quantity etc.) the more detailed the better, leave us an inquiry or email to us and we will response promptly!

Q : How to get a free sample?

A : We can provide our existing similar samples for free to check the style and quality! For sample with your own logo or design, mold fee will be charged base on specification.

Q : What's the payment method?

A : It is very convenient And TT,LC...are all available.

Q : What's the process of order?

A : Send us Inquiry →get quotation → payment done →open mold and make samples →deliver you samples or send you pictures of samples for approval → mass production.

Q : When can l expect the customized product to be finished?

A : Sample:7-10 working days (Standard).Bulk order: 10-25 working days (Standard). If you have any other questions, please feel free to contact us!

PLEASE GIVE US A MESSAGE

YOBEST (YBT) METAL

8

Workshops

100.000 m2

Factory Area

3000 tons

Monthly capacity

Assurance

*We respect your confidentiality and all information are protected. Maybe the time difference, We will respond to your inquiry message within 12 hours at the latest.