Search

Categories List

Message

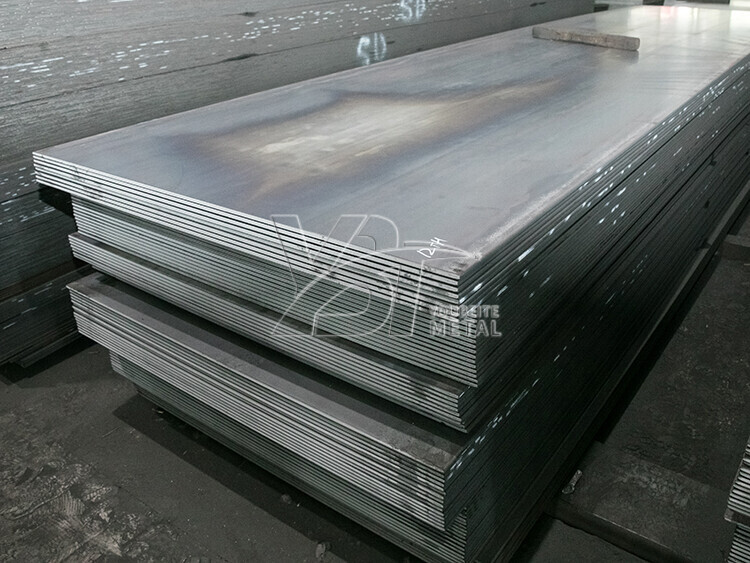

Available Carbon Steel Grades:ZGMn13-1,For more material grades, Please click

Payment Term:TT,L/C,etc

Price Term:Ex-Work,FOB,CNF,CFR,etc

MOQ:1Ton

Delivery Time:Usually 7-30days, or upon negotiation

Loading Port:TIANJIN,SHANGHAI,DALIAN ,QINGDAO,etc

If you have any questions, please feel free to contact us.

Wear Resistance of Manganese Plate

Grade

GB:ZGMn13-1、ZGMn13-2、ZGMn13-3、ZGMn13-4、ZGMn13-5

ASTMA:ASTM-A(UNS-J91109)、ASTM-B-1(UNS-J91119)、ASTM-B-2(UNS-J91129)、ASTM-B-3(UNS-J91139)、ASTM-B-4(UNS-J91149)、ASTM-C(UNS-J91309)、ASTM-D(UNS-J91459)、ASTM-E-1(UNS-J91249)、ASTM-E-2(UNS-J91339)

JISG:SCMnH1、SCMnH2、SCMnH3、SCMnH11、SCMnH21

ISO:GX120MnMo7-1、GX110MnMo13-1、GX100Mn13、GX120Mn13、GX120MnCr13-2、GX120MnNi13-3、GX120Mn17、GX90MnMo14、GX120MnCr17-2

Chemical Composition (Typical)/ Chemistry of Manganese Steel Plate :

Mechanical characteristics:

Wear Resistant Materials:

WARRIORS ACRONI, X12, 11- 14 % MANGANESE

PLATEWARRIORS ACRONl. X12. 11- 14 % Manganese is a true Hadfield

Austenitic Manganese steel for resistance to severe impactand abrasive

wear. lt is work hardening steel.

WORK HARDENING refers to the fact that the steel becomes harder and harder the more it is impacted or compressed

The "Hadfield" grade has an original hardness of approximately 220 Brinel. With continued impact and /or compression it wilsurface harden to over 550 Brinel. lt should be noted that only the outer skin surface hardens. The under layer remains highlyductile and tough. As the surface wears, it continualy renews itself becoming harder and harderManganese steel is austenitic steel which means it is non-magnetic. This property makes it useful in many applications such asbottom plates for lifting magnets - separator drum shells for magnetic materials -- wear shoes on electric brakes etc.

Q: How do you control quality?

A : Mill Test Certification is supplied with shipment, Third Party Inspection isavailable.and we also get ISO,SGS,Alibaba Verified.

Q : What are the advantages of your company?

A : We have many professionals,technical personnel, more competitiveprices and best after-dales service than other steel companies.

Q : What extra services do you offer?

A : We can provide you with roll splitting, size cutting, surface treatment(galvanizing, coating and sandblasting) and other services according toyour requirements.

Q: How can l get a quotation?

A : Kindly provide us your details request (item No, style, logo, size, material, surface treatment, quantity etc.) the more detailed the better, leave us an inquiry or email to us and we will response promptly!

Q : How to get a free sample?

A : We can provide our existing similar samples for free to check the style and quality! For sample with your own logo or design, mold fee will be charged base on specification.

Q : What's the payment method?

A : It is very convenient And TT,LC...are all available.

Q : What's the process of order?

A : Send us Inquiry →get quotation → payment done →open mold and make samples →deliver you samples or send you pictures of samples for approval → mass production.

Q : When can l expect the customized product to be finished?

A : Sample:7-10 working days (Standard).Bulk order: 10-25 working days (Standard). If you have any other questions, please feel free to contact us!

PLEASE GIVE US A MESSAGE

YOBEST (YBT) METAL

8

Workshops

100.000 m2

Factory Area

3000 tons

Monthly capacity

Assurance

*We respect your confidentiality and all information are protected. Maybe the time difference, We will respond to your inquiry message within 12 hours at the latest.